920-726-4526

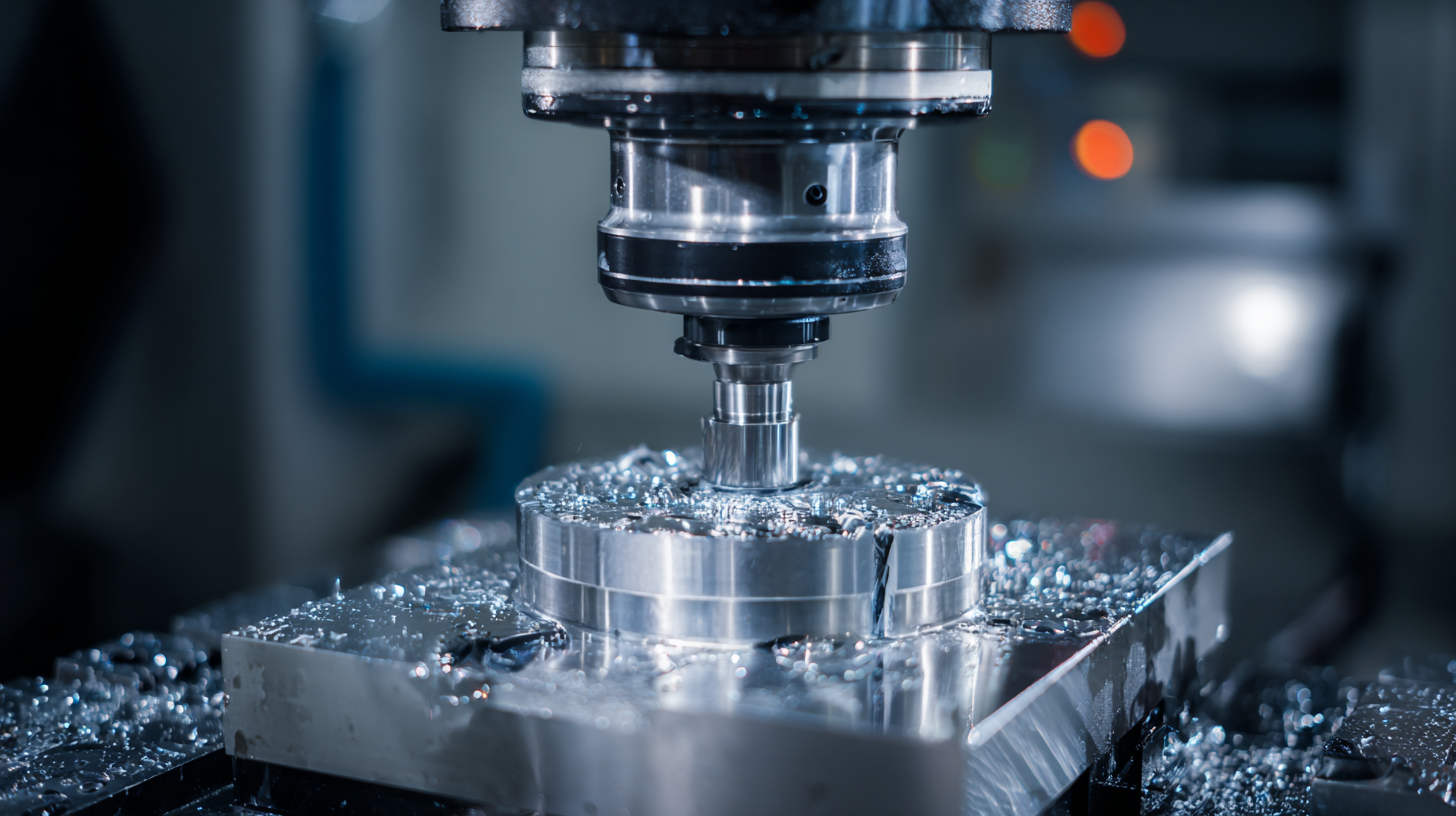

In the world of precision machining, the choice of equipment can significantly impact the quality and efficiency of the production process. Among the various machining tools available, a CNC mill stands out as an exceptional option for businesses looking to enhance their operational capabilities in 2023. With advancements in technology and an increasing demand for high precision components across various industries, the CNC mill has become a preferred choice for manufacturers.

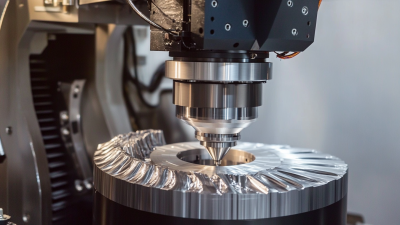

CNC mills provide unparalleled accuracy and repeatability, essential for producing intricate parts that meet strict tolerances. This ability to consistently deliver high-quality results makes CNC mills an indispensable tool for industries like aerospace, automotive, and medical devices. Furthermore, the versatility of CNC mills allows them to handle a wide range of materials, from metals to plastics, making them suitable for diverse applications.

As we delve into the top ten reasons why you should consider a CNC mill for your precision machining needs this year, you'll discover the unique benefits they offer, including increased productivity, reduced labor costs, and enhanced design capabilities. Embracing the power of a CNC mill in your manufacturing process could ultimately lead to significant gains in quality and efficiency, setting your business up for success in a competitive market.

CNC milling has surged in popularity over traditional machining techniques due to its remarkable precision and efficiency. Unlike manual machining, CNC mills utilize computer numerical control, allowing for intricate designs and complex geometries to be produced with minimal human intervention. This automation leads to a significant reduction in human error, ensuring that each part manufactured meets exact specifications consistently. Moreover, CNC milling can handle a variety of materials, making it an adaptable choice for diverse industries.

When considering a transition to CNC milling, keep these tips in mind: first, assess your specific machining requirements. Different projects may require varying levels of precision and complexity, and understanding your needs will help you select the right equipment. Second, consider investing in training for your staff to maximize the benefits of CNC technology. Skilled operators can better leverage the machine’s capabilities, leading to higher productivity and improved quality of output.

Additionally, embracing CNC milling can lead to cost savings in the long run. The faster production times and reduced waste from precise cuts mean that businesses can operate more efficiently. This improved efficiency not only enhances output but can also contribute to better customer satisfaction by allowing quicker turnaround times on orders.

When considering precision machining needs in 2023, selecting the right CNC mill is crucial. As the global CNC machine market is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032 at a CAGR of 9.9%, understanding the key features to look for in a CNC mill becomes increasingly important for manufacturers and small businesses alike.

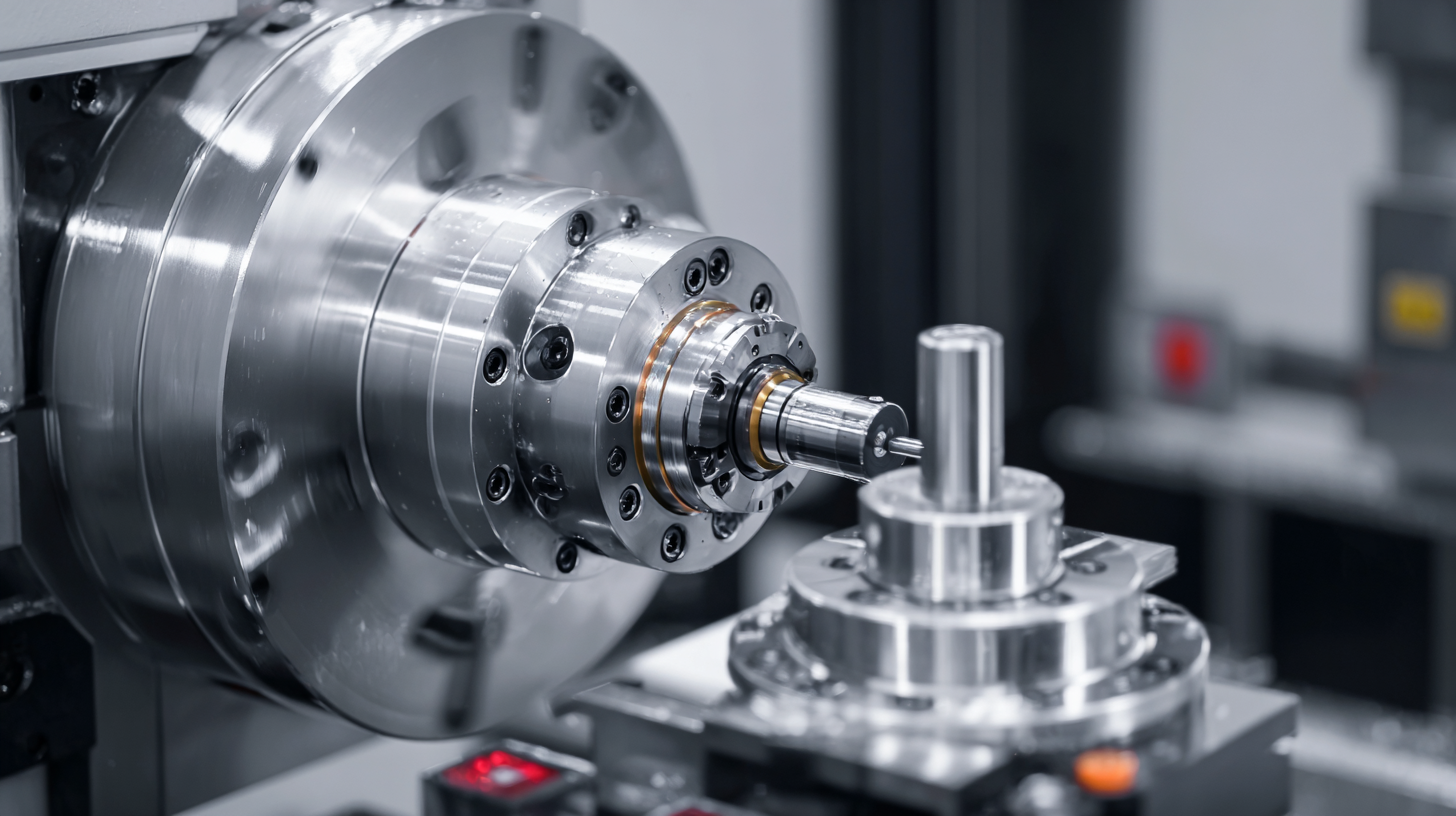

One of the primary features to consider is precision. A CNC mill must deliver consistent accuracy to produce high-quality parts that meet stringent specifications. Features such as advanced motion control systems and improved spindle designs can enhance precision, making it easier to achieve tight tolerances. Furthermore, automation capabilities, such as IoT integration, are essential for streamlining operations and reducing manual intervention, thus increasing efficiency and productivity. With the right CNC mill, businesses can capitalize on the growing demand for precision machining, ultimately driving their success in an expanding market.

Additionally, the cooling system is another critical aspect. Modern CNC mills equipped with superior cooling capabilities can significantly improve tool life and performance, especially when machining materials like aluminum. As seen in products such as the high-performing CNC aluminum cases designed for efficient thermal management, these features not only enhance productivity but also ensure the longevity of machinery, solidifying the importance of quality in the selection process.

CNC milling technology has found extensive applications across various industries due to its precision and efficiency. In sectors such as aerospace and automotive, CNC mills are used to produce intricate components that require exact specifications, ensuring safety and performance standards are met. The growth in these industries is reflected in the machine shop services market, projected to reach USD 90.31 billion by 2033, highlighting the increasing reliance on CNC machining for precision tasks.

Moreover, advancements in CNC machining technologies are enabling manufacturers to create high-quality components from materials like stainless steel. This trend is crucial as industries demand more durable and reliable parts, driving innovation within CNC milling processes. As companies continue to adopt digital manufacturing technologies, the productivity and flexibility of CNC mills are expected to improve further, making them indispensable for modern precision machining needs across various sectors.

| Industry | Application | Material Used | Precision Level | Typical Tolerance |

|---|---|---|---|---|

| Aerospace | Component Manufacturing | Aluminum Alloys | High Precision | ±0.001 inches |

| Automotive | Engine Parts Manufacturing | Steel Alloys | Medium Precision | ±0.002 inches |

| Medical | Surgical Instruments | Stainless Steel | High Precision | ±0.001 inches |

| Electronics | Circuit Board Components | Copper | High Precision | ±0.005 inches |

| Renewable Energy | Turbine Components | Carbon Composite | Medium Precision | ±0.002 inches |

CNC milling has emerged as a cost-effective solution for both small and large-scale projects in 2023. According to a report from Grand View Research, the global CNC machining market is projected to reach USD 100 billion by 2025, demonstrating a Compound Annual Growth Rate (CAGR) of 8.1%. This growth indicates that businesses are increasingly recognizing the financial advantages of embracing CNC technology, which offers precision and consistency at reduced labor costs. By automating machining processes, companies can achieve faster production times, ultimately lowering overall project expenses.

For small businesses, CNC milling provides an opportunity to compete with larger manufacturers without incurring prohibitive costs. The initial investment in a CNC mill can yield significant savings. A study from the National Association of Manufacturers (NAM) highlights that nearly 70% of manufacturers save on labor costs by using CNC machines. This savings is amplified in large projects that require repetitive tasks, as CNC milling can maintain uniformity and quality across numerous parts, eliminating the risks of human error and minimizing wastage. Thus, both scalability and dependability make CNC milling a sound financial choice across various project sizes.

The CNC milling technology is evolving rapidly, driven by advancements in digital manufacturing. In 2023, precision machining is witnessing a significant increase in productivity across various industries due to the integration of cutting-edge tools and automation. These innovations allow for higher accuracy and faster production times, making CNC mills a preferred choice for manufacturers looking to enhance efficiency and quality in their operations.

The woodworking CNC tools market exemplifies this growth, projected to expand from USD 8.2 billion in 2025 to USD 13.4 billion by 2035, with a compound annual growth rate of 5.0%. This trend indicates a strong demand for precision machining across sectors, highlighting the need for businesses to adopt modern CNC technologies. Furthermore, the global CNC metal cutting machine tools market continues to grow, as industries recognize the benefits of refining their machining processes to meet increasing quality standards and production demands. The continuous evolution of CNC milling technologies promises exciting opportunities for enhanced precision in manufacturing.

5107 County Road C

Manitowoc, WI 54220

920-726-4526