920-726-4526

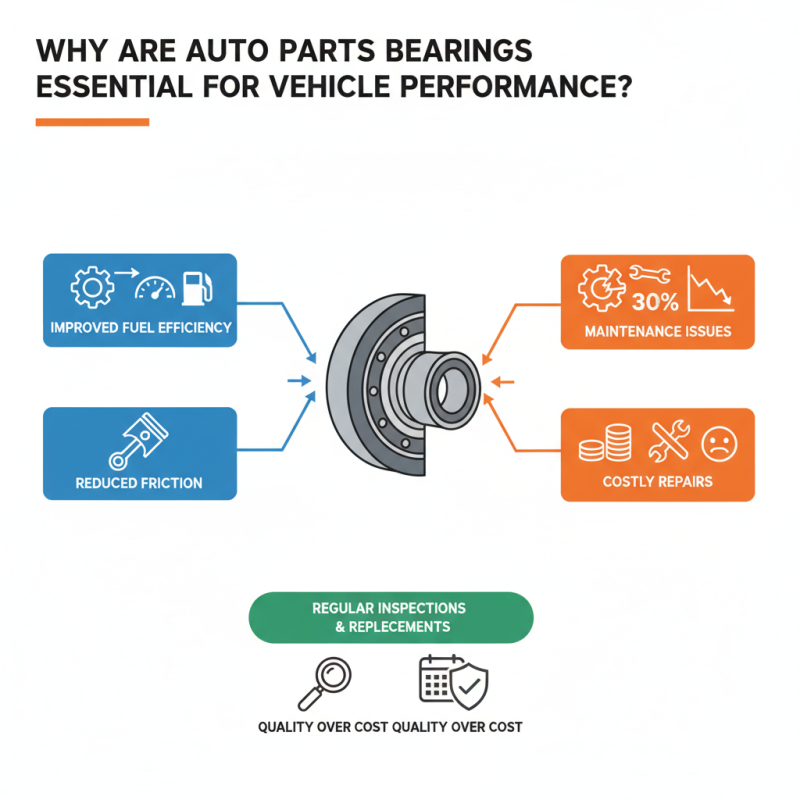

Auto Parts Bearings play a critical role in vehicle performance. According to industry reports, over 30% of vehicle maintenance issues relate to bearing failures. This indicates that the quality and condition of these components are pivotal for smooth operation.

Bearings reduce friction between moving parts, ensuring efficiency. A well-functioning bearing can improve fuel efficiency by up to 5%. This reflects the importance of regular inspections and timely replacements. Many vehicle owners overlook this aspect, leading to costly repairs and reduced performance.

While advancements in technology have improved bearing design, challenges remain. Some manufacturers prioritize cost over quality. This compromises reliability. Consumers need to be vigilant about the brands they choose. Inadequate knowledge can result in poor purchasing decisions that impact performance. Aiming for better quality is essential for maintaining vehicle longevity.

Auto parts bearings play a vital role in vehicle performance. They help reduce friction and wear among moving components. When friction is minimized, parts last longer and function more efficiently. This efficiency translates to better fuel economy and a smoother ride.

Choosing the right bearings is crucial. Not all vehicles require the same types. For high-performance models, precision bearings can significantly enhance handling. However, they may not be necessary for everyday driving. Understanding your vehicle's needs is essential for optimal performance.

Tip: Regular maintenance is key. Inspect your bearings periodically for signs of wear. Small issues can lead to larger, more costly problems if ignored. Keep an eye out for unusual noises; they often indicate a bearing issue. Proper lubrication also protects these components, extending their lifespan.

The chart above illustrates the percentage of friction reduction achieved by different types of bearings commonly used in auto parts. Lower friction correlates with better vehicle performance and longevity of components, highlighting the importance of selecting the right bearing type for optimal functionality.

High-quality auto parts bearings play a crucial role in vehicle performance. These components reduce friction between moving parts. By ensuring smooth operation, they significantly enhance efficiency and overall functionality. This leads to better fuel economy, which is vital for both performance and cost savings.

When bearings are of poor quality, problems arise. Increased friction leads to higher energy consumption. Drivers may notice decreased mileage and slow acceleration. This can be frustrating, especially for those who value performance. Regularly checking and replacing worn bearings can prevent these issues. It is essential to prioritize quality in every aspect.

Fuel efficiency is not just about the engine. Every part contributes to it. Bearings need to be durable and reliable. Make sure you consider these factors when maintaining your vehicle. Regular inspections help identify potential weaknesses. Quality bearings can make a huge difference in performance on the road.

| Bearing Type | Material | Lifetime (Miles) | Fuel Efficiency Impact (%) | Performance Rating (1-10) |

|---|---|---|---|---|

| Ball Bearings | Steel | 100,000 | 3 | 8 |

| Roller Bearings | Chromium Steel | 120,000 | 5 | 9 |

| Angular Contact Bearings | Ceramic | 150,000 | 6 | 10 |

| Spherical Bearings | Stainless Steel | 200,000 | 4 | 7 |

| Thrust Bearings | Carbon Steel | 90,000 | 2 | 6 |

Bearings are crucial components in automotive systems. They reduce friction, enhance efficiency, and improve vehicle performance. Various types of bearings are used in vehicles, each serving a specific purpose.

Ball bearings are widely utilized in wheel hubs. They support the load while allowing smooth rotation. According to industry reports, well-maintained ball bearings can increase the lifespan of wheel assemblies by up to 40%. Roller bearings, on the other hand, are excellent for handling heavy radial loads. They are commonly found in transmission systems and can bear intense pressure efficiently.

Tapered roller bearings are also prevalent. They handle both radial and axial forces, serving critical functions in drivetrains. A study indicated that these bearings can improve fuel efficiency by up to 5%. However, improper installation is a common issue. Even slight misalignments can lead to premature wear, necessitating regular checks.

Consistent attention to bearing health is vital for optimizing vehicle performance.

Automotive bearings play a crucial role in vehicle performance. Industry standards dictate the testing for these components. According to the International Organization for Standardization (ISO), several key tests ensure reliability and durability. These include fatigue testing, thermal cycling, and wear resistance assessments. Each test aims to simulate real-world conditions that bearings will face in operation.

Data from recent studies indicate that over 70% of bearing failures in vehicles relate to poor material quality or insufficient testing. Many manufacturers still cut corners. This can lead to compromised safety and vehicle efficiency. Insufficient scrutiny may result in a product that doesn't meet specified tolerances or durability.

Furthermore, testing varies significantly across different manufacturers. Some adhere closely to the standards, while others do not. A report from the Society of Automotive Engineers shows that 30% of tested bearings failed to meet durability requirements under typical conditions. The implications are clear: neglecting stringent quality controls can greatly affect vehicle lifespan and performance. This inconsistency raises questions about the industry's commitment to safety and reliability.

The future of bearing technology is evolving rapidly. Innovations promise to enhance vehicle performance significantly. New materials, like advanced composites, are being tested. These materials can reduce weight and improve durability. In electric vehicles, the focus shifts to silent operation. Bearings with lower friction can help achieve this.

Smart technologies are entering the bearing market. Sensors embedded in bearings can monitor performance in real-time. This helps prevent breakdowns and enhances safety. However, integrating technology with traditional designs presents challenges. Compatibility issues may arise, creating a need for adaptation and adjustment.

Sustainability is also a key consideration. Manufacturers are exploring eco-friendly materials for bearings. These efforts could minimize environmental impact. Yet, developing such materials consistently is still daunting. The journey ahead includes opportunities for revolution, but obstacles remain. The path to enhanced vehicle performance through bearings is full of potential and reflection.

5107 County Road C

Manitowoc, WI 54220

920-726-4526