920-726-4526

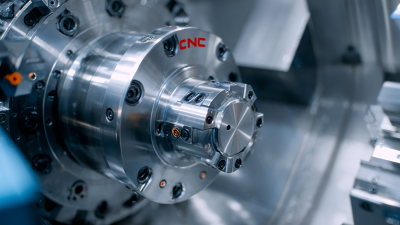

In the world of precision manufacturing, CNC turning has emerged as a pivotal technique that enhances accuracy and efficiency in machining processes. According to a recent industry report by MarketsandMarkets, the global CNC machine market is projected to reach $117 billion by 2026, with a significant segment attributed to CNC turning technologies. This surge is driven by increasing demand for high-precision components in sectors such as aerospace, automotive, and medical devices. Mastering CNC turning techniques is essential for manufacturers aiming to maintain a competitive edge in today's fast-paced environment. By honing skills in CNC turning, operators can achieve Tighter Tolerances, Reduced Cycle Times, and Improved Surface Finishes, ultimately leading to superior product quality and cost-effectiveness. Embracing best practices and advanced methodologies in CNC turning will not only enhance operational capabilities but also ensure alignment with industry standards and customer expectations.

CNC turning is a crucial component in achieving superior precision in manufacturing operations. Understanding the basics of CNC turning machines and their operations is essential for any machinist looking to enhance their skills. CNC turning machines, which automate the rotation of materials for cutting, rely on precise programming and control to achieve accurate dimensions and surface finishes. The integration of advanced CNC systems offers machine operators the ability to fine-tune operations and achieve enhanced performance metrics.

Recent advancements in CNC technology highlight the importance of effective process management. For instance, process damping during milling operations has been recognized as a critical factor in maintaining machining stability and efficiency. By applying similar principles to CNC turning, operators can mitigate vibrations that affect precision. Additionally, balancing tools is vital; improper balance can result in poor performance and wear, which impacts the quality of the finished product. Utilizing modern software solutions can further aid in refining the control over these processes, ensuring that CNC turning achieves the desired outcomes consistently and reliably.

According to industry reports, implementing comprehensive training and utilizing cutting-edge CNC systems can lead to a significant reduction in production errors. This highlights the necessity for technicians to be well-versed in the fundamentals of CNC operations to capitalize on advancements in technology. Therefore, continuous education in CNC turning techniques is essential for mastering the art of precision manufacturing.

To master CNC turning techniques for superior precision, it's crucial to focus on essential tools and equipment that define the capabilities and efficiency of the machining process. At the forefront of modern machining technology is the evolution of CNC turning centers that integrate advanced automation and digitalization, significantly enhancing precision and productivity. According to industry forecasts, the global machine tools market, valued at approximately $97.1 billion in 2024, is expected to nearly double by 2034, indicating a compelling shift towards higher precision machinery that meets evolving manufacturing demands.

The JIMTOF 2024 highlighted innovations that are shaping future production processes, particularly in the area of high-precision turning-milling machine tool designs. Research into multi-objective optimization design, utilizing methodologies such as the Taguchi method, emphasizes the importance of structural integrity in machine tool beds, which are critical for enhancing load-bearing capacities and improving machining accuracy. Furthermore, advanced finite element analysis (FEA) plays a pivotal role in optimizing the design of these tools, ensuring that their dynamic, static, and rigidity characteristics align with the demands of high-precision machining. As automation continues to transform CNC machining processes, the need for sophisticated components becomes increasingly important to eliminate human error and sustain the highest levels of performance.

Setting up and calibrating CNC turning tools is critical to achieving superior precision in machining. Effective calibration ensures that tools operate within the specified tolerances, enhancing product quality and reducing waste. According to industry reports, the accuracy of a CNC machine can degrade over time, with misalignment contributing to an average decline in precision by approximately 10% annually if not properly checked and adjusted. Implementing a comprehensive calibration schedule can mitigate these effects, ensuring that machines remain aligned and function optimally.

The process of calibration begins with meticulous alignment procedures, often employing advanced measurement tools such as optical lasers. Research shows that proper alignment can significantly enhance the overall repeatability of CNC turning operations, boosting efficiency and reducing downtime. In fact, machines that regularly undergo alignment checks can achieve up to 30% improved productivity compared to those that do not. By adopting these techniques, manufacturers can not only increase the longevity of their CNC turning tools but also uphold high standards of precision throughout the production process.

CNC turning is an essential component of precision machining, but it often presents several challenges that can hinder production efficiency and accuracy. One common issue in CNC turning is tool wear, which can lead to suboptimal machining results. To overcome this, operators should implement regular tool inspections and adopt a predictive maintenance schedule. Using high-quality cutting tools and establishing proper feed rates can also significantly reduce wear and extend tool life.

Another challenge faced in CNC turning is managing programming errors, which can cause dimensional inaccuracies. To address this, operators should embrace simulation software to visualize the machining process before actual production. This can help identify potential programming errors early in the workflow. Additionally, thorough training for operators on the latest CNC programming techniques and software can enhance overall proficiency, ensuring that precision is prioritized throughout the machining process. By proactively addressing these common challenges, manufacturers can achieve superior precision in their CNC turning operations.

To maintain and optimize CNC turning performance, it's essential to focus on several key techniques that enhance precision while prolonging machine life. Regular maintenance schedules should be established, including routine checks of tools, coolant levels, and alignment settings. Keeping tools sharp and well-calibrated minimizes wear and tear, ensuring that any turning operations yield consistent results.

Furthermore, implementing advanced technology and software solutions can significantly enhance performance. Utilizing monitoring systems allows operators to track real-time machine data, identifying potential issues before they escalate.

Adjusting parameters such as feed rates and spindle speeds based on material properties can also lead to improved precision and efficiency. Additionally, conducting regular training sessions for machine operators on best practices further contributes to maintaining optimum performance levels, ensuring that your CNC turning operation remains competitive and precise.

5107 County Road C

Manitowoc, WI 54220

920-726-4526