920-726-4526

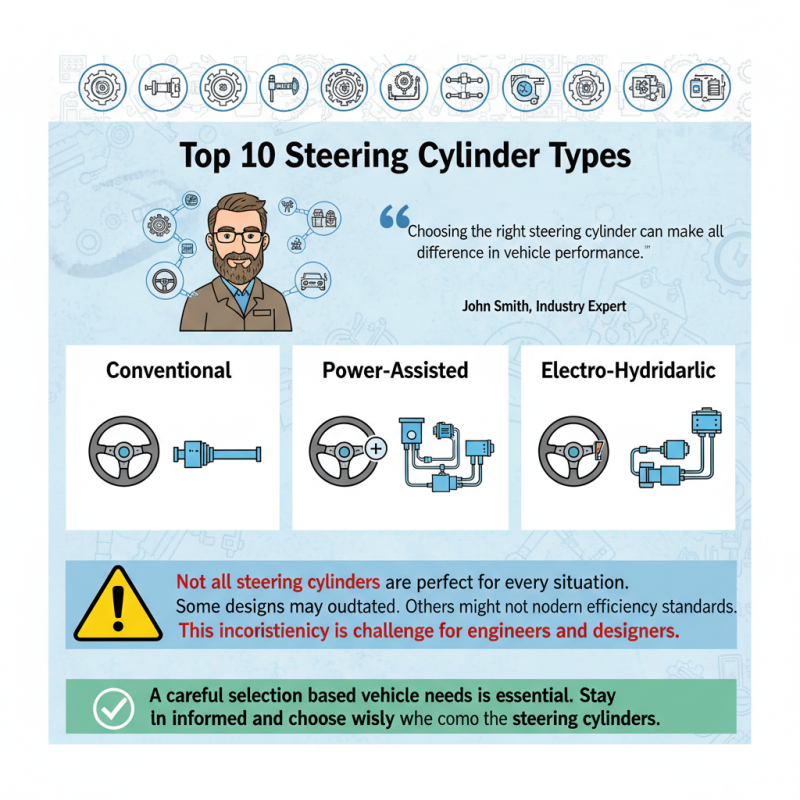

In the world of automotive engineering, understanding the various Steering Cylinder types is crucial. John Smith, an industry expert, once said, "Choosing the right steering cylinder can make all the difference in vehicle performance." This emphasizes the importance of steering cylinders in ensuring safety and efficiency in vehicles.

Steering cylinders play a vital role in the steering system. They convert hydraulic pressure into mechanical force. Different types of steering cylinders exist, each designed for specific applications. These include conventional, power-assisted, and electro-hydraulic types. Knowing their functions can help in making informed decisions for automotive design.

However, not all steering cylinders are perfect for every situation. Some designs may be outdated. Others might not meet modern efficiency standards. This inconsistency is a challenge for engineers and designers. A careful selection based on vehicle needs is essential. Stay informed and choose wisely when it comes to steering cylinders.

Steering cylinders play a crucial role in vehicle handling and performance. They are responsible for converting hydraulic pressure into mechanical force. This force then helps to pivot the wheels, allowing for smooth turns and precise navigation. In both cars and industrial machinery, their functionality is indispensable. A malfunctioning steering cylinder can lead to severe control issues, resulting in unsafe driving conditions.

Tips for maintaining your steering cylinder include regular inspections. Check for leaks or signs of wear. It’s easy to overlook these components, but neglect can lead to costly repairs. Having a routine maintenance schedule is essential. Furthermore, ensure the hydraulic fluid is at the correct level and quality. Low fluid levels can impair steering responsiveness.

Every driver should understand the importance of steering components. However, many overlook them until problems arise. Familiarize yourself with different steering cylinder types. Learn how each operates. This knowledge empowers you to identify issues sooner. Be proactive in learning and maintaining your vehicle's components to ensure safety and performance.

| Steering Cylinder Type | Functionality | Importance | Typical Applications |

|---|---|---|---|

| Single Acting Cylinder | Uses hydraulic pressure for one-directional motion. | Simple design, cost-effective, and reliable. | Lightweight vehicles and steering applications. |

| Double Acting Cylinder | Provides motion in both directions using hydraulic pressure. | Increased control and efficiency in steering. | Heavy-duty vehicles and industrial machinery. |

| Telescopic Cylinder | Multi-stage design allows for extended reach. | Ideal for applications where space is limited. | Agricultural equipment and compact vehicles. |

| Rams | Transmits force in a straight line for steering movement. | High strength and durability for heavy loads. | Heavy machinery and construction equipment. |

| Rack and Pinion Cylinder | Converts rotational motion into linear motion. | Offers precise steering controls. | Passenger cars and small trucks. |

| Hydrostatic Steering Cylinder | Allows steering without direct mechanical link. | Minimizes wear and facilitates smoother handling. | Boats and specialized transport vehicles. |

| Power Steering Cylinder | Uses hydraulic pressure to assist in turning the steering wheel. | Enhances driver comfort and control. | Most modern passenger vehicles. |

| Variable Ratio Steering Cylinder | Adjusts the steering ratio based on speed and conditions. | Improves safety and responsiveness. | High-performance vehicles and sports cars. |

| Electric Steering Cylinder | Uses electric motors for steering assistance. | Increased energy efficiency and reduced mechanical wear. | Hybrid and electric vehicles. |

| Load-Sensing Steering Cylinder | Adapts hydraulic flow based on load and speed. | Optimizes performance and responsiveness. | Trucks and heavy machinery. |

Hydraulic steering cylinders play a vital role in many applications. They help control the direction of vehicles and machinery efficiently. These units convert hydraulic energy into mechanical force. This action provides smooth steering functions.

In design, hydraulic steering cylinders often feature a robust structure. They must withstand high pressures and heavy loads. Sealing systems are crucial to prevent leaks. Failures in seals can lead to significant operational issues. Regular checks can help identify potential problems early.

Tips: Ensure your hydraulic system is properly maintained. Regularly inspect hoses and fittings for wear and tear. Monitor fluid levels to avoid system failures. Consider using filters to keep the hydraulic fluid clean.

These cylinders find use in various fields, from construction to agriculture. Each application presents unique challenges. Users should adapt cylinder selection to specific needs. Incorrect choices can lead to inefficiencies. Invest time in understanding requirements and capabilities.

Mechanical steering cylinders play a crucial role in various machinery. They convert rotational motion into linear movement. These cylinders are vital in industries such as automotive, aerospace, and construction. The precision in steering increases operational efficiency. According to a market analysis, the mechanical steering systems market is projected to reach $3.2 billion by 2025. This suggests high demand across sectors.

There are several types of mechanical steering cylinders, each with unique applications. For instance, dual-acting cylinders offer enhanced control and responsiveness. They are popular in heavy equipment. But they can be more complex to maintain. Single-acting cylinders are simpler but lack the versatility of their dual-acting counterparts. Industry data indicates that single-acting cylinders make up about 40% of the market share. This highlights their ongoing relevance.

Despite advancements, some challenges remain. For example, the seal wear in hydraulic systems can lead to performance declines. Routine maintenance is essential but often overlooked. User education about these issues could improve longevity. Understanding the types and their specific use cases is essential for optimal performance.

Electric steering cylinders bring a wave of change to automotive technology. They offer precision control and improved efficiency. This innovation helps in making vehicles more responsive to driver inputs. Electric systems also reduce the mechanical complexity often found in traditional steering systems. As a result, there is less maintenance involved, which is attractive to many drivers.

When considering electric steering cylinders, it is essential to look at power consumption. Some designs can drain battery life quickly, especially in electric vehicles. This trade-off can affect overall performance and longevity. It's crucial to evaluate the system's efficiency against the vehicle's needs.

Tip: Always assess your driving habits. If you frequently navigate tight spaces, electric steering can enhance your experience significantly.

Moreover, the technology is still evolving. Some electric cylinders may lack the feedback traditional systems provide. This could create a disconnect between driver and vehicle. Awareness of these factors is necessary for informed decisions.

Tip: Test drive vehicles with electric steering. Pay attention to how it feels and responds. This hands-on experience will help you understand the advantages and limitations better.

Choosing the right steering cylinder is crucial for your vehicle's performance. With various types available, understanding their differences can optimize your driving experience. According to industry reports, improper selection can lead to steering failures. This not only affects control but also safety on the road.

Tip: Assess your vehicle’s weight and intended use. Lighter vehicles may benefit from a smaller, lighter steering cylinder. Conversely, heavier vehicles often require robust designs for durability. This alignment enhances performance and prolongs component lifespan.

Pay attention to design features. Dual-action cylinders provide more precise control. However, they can be more complex than single-action types. Not all steering cylinders are created equal. Some might be suited for off-road use, while others excel in urban environments.

Tip: Consider maintenance needs. Some cylinders require frequent checks, while others are designed for low maintenance. Evaluate your comfort level with upkeep. A well-chosen cylinder can greatly enhance your vehicle's handling and comfort. But choosing blindly can lead to issues. Reflect on your specific driving habits and needs. This could prevent costly mistakes down the road.

5107 County Road C

Manitowoc, WI 54220

920-726-4526